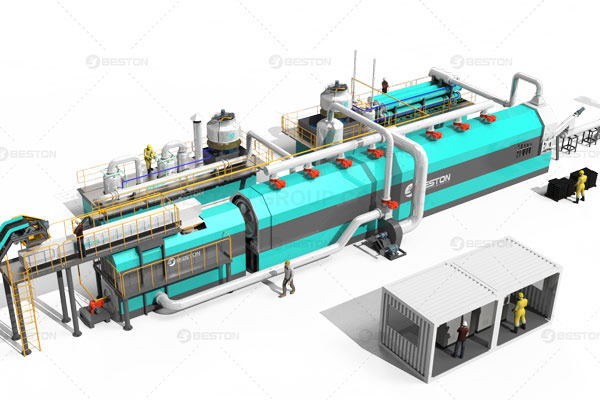

Running a pyrolysis plant efficiently involves managing various operational costs, especially for continuous systems that run non-stop. Operational cost optimization is essential for maintaining profitability and ensuring the plant operates within budgetary constraints. This article delves into the key strategies and considerations for reducing costs without compromising the plant’s performance or product quality.

Understanding the Cost Structure of a Continuous Pyrolysis Plant

Before diving into cost optimization strategies, it’s crucial to understand the primary cost drivers in a continuous tyre pyrolysis plant. The most significant operational expenses are energy consumption, feedstock handling, maintenance, labor, and waste management. Continuous pyrolysis systems, which operate around the clock, tend to have higher energy requirements and wear and tear on equipment, making cost control a critical factor for long-term success.

Energy is typically the largest operational expense for pyrolysis plants, as the process requires a substantial amount of heat to break down feedstock into valuable products such as bio-oil, syngas, and biochar. Feedstock handling also represents a significant cost due to the transportation, storage, and pre-treatment of raw materials before pyrolysis. In addition, ongoing maintenance is essential to ensure that the plant runs smoothly and that unexpected breakdowns do not lead to costly downtime.

Energy Efficiency Strategies

One of the most effective ways to reduce operational pyrolysis plant cost is by improving energy efficiency. Optimizing heat recovery systems is key. A well-designed heat recovery system can capture and reuse heat from the process, reducing the amount of external energy required. This can significantly lower fuel consumption, especially for high-temperature operations typical in continuous pyrolysis systems.

Another strategy involves improving the reactor design. More efficient reactors that allow for better heat distribution can reduce energy losses and increase the overall thermal efficiency of the pyrolysis plant. Additionally, employing advanced technologies such as solar pre-heating or using waste heat from other processes can provide an alternative energy source, reducing dependence on traditional fuels.

Feedstock Management and Pre-Treatment

Feedstock costs can fluctuate depending on availability, transportation costs, and quality. Efficient feedstock management can contribute significantly to lowering operational costs. One way to optimize feedstock costs is through sourcing low-cost, high-energy-density materials. Waste plastics, rubber, or agricultural residues may provide a more affordable feedstock for pyrolysis, particularly when compared to higher-cost options like wood chips.

Pre-treatment of feedstock can also reduce costs during the pyrolysis process. Feedstocks that are consistent in size, moisture content, and composition allow the pyrolysis plant to operate more efficiently. Pre-treatment steps such as drying, grinding, and sorting can help ensure that the feedstock is optimal for pyrolysis, improving the overall yield and reducing energy consumption during the thermal decomposition process.

Automation and Process Control

Automation plays a critical role in optimizing the operational costs of continuous pyrolysis plants. By incorporating advanced process control systems, plants can continuously monitor and adjust operating parameters to ensure maximum efficiency. Automation helps to streamline operations, reduce human error, and minimize labor costs.

Moreover, an advanced control system can provide real-time data on process performance, enabling plant operators to detect inefficiencies early and adjust parameters accordingly. This can lead to more stable operations, reducing the risk of costly errors or unplanned downtime. For instance, managing temperature, pressure, and residence time in real-time can prevent over-consumption of energy or inefficient feedstock conversion. For information on advanced pyrolysis technology, please contact Beston Group Co., Ltd.

Maintenance Strategies to Minimize Downtime

Scheduled maintenance is essential in reducing long-term operational costs by preventing costly breakdowns. A well-planned preventive maintenance schedule ensures that equipment is regularly serviced and kept in optimal working condition. It also helps identify components that are wearing out or showing signs of damage, which can be replaced before they lead to expensive repairs or prolonged downtime.

Additionally, predictive maintenance systems, which use sensors and data analytics to predict when a part is likely to fail, can help reduce unplanned downtime. By replacing worn components before they break, the plant can maintain continuous operation without costly interruptions.

Waste Management and Byproduct Utilization

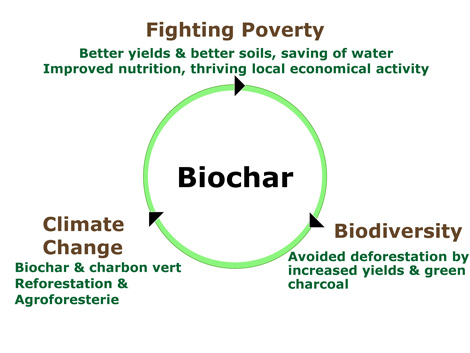

Pyrolysis plants generate a variety of byproducts, including syngas, biochar, and liquid fuels. Efficiently managing these byproducts can help offset some operational costs. For example, syngas can be used within the plant to generate electricity or heat, reducing the need for external energy sources. Similarly, biochar can be sold as a high-value product, used in applications ranging from soil enhancement to carbon sequestration.

By optimizing the recovery and use of byproducts, the plant can turn potential waste into a revenue-generating resource, thus improving the overall cost-efficiency of the operation. Additionally, managing waste generated during the pyrolysis process, such as tar and other residues, can help prevent contamination and reduce the cost of disposal.

Conclusion: Striking a Balance for Sustainable Operation

Optimizing the operational costs of a continuous pyrolysis plant requires a multifaceted approach that addresses energy efficiency, feedstock management, automation, maintenance, and byproduct utilization. By implementing these strategies, plant operators can reduce expenses while improving the efficiency of the pyrolysis process. This will not only contribute to a more profitable operation but also enhance the sustainability of the pyrolysis plant, positioning it as a viable long-term solution for waste management and resource recovery.